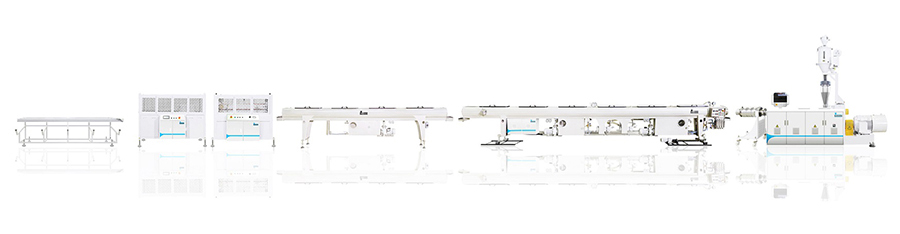

High Energy Efficiency PPR Pipe Production Line with Coiler and Packing Machine

Product Applications

In recent years, with the improvement of living standards and the continuous increase of market demand in the construction industry, municipal engineering, and commercial housing development, PPR pipe has gradually become a new type of product commonly used in developed countries. Its technical performance is far superior to other similar pipe products. Especially its environmentally friendly performance ensures that it will not cause any heavy metals contamination. More and more cold and hot water pipeline systems adopts PPR pipes in domestic market for the transportation of drinking water and food industries due to the outstanding environmental protection advantages in pure water pipeline systems.

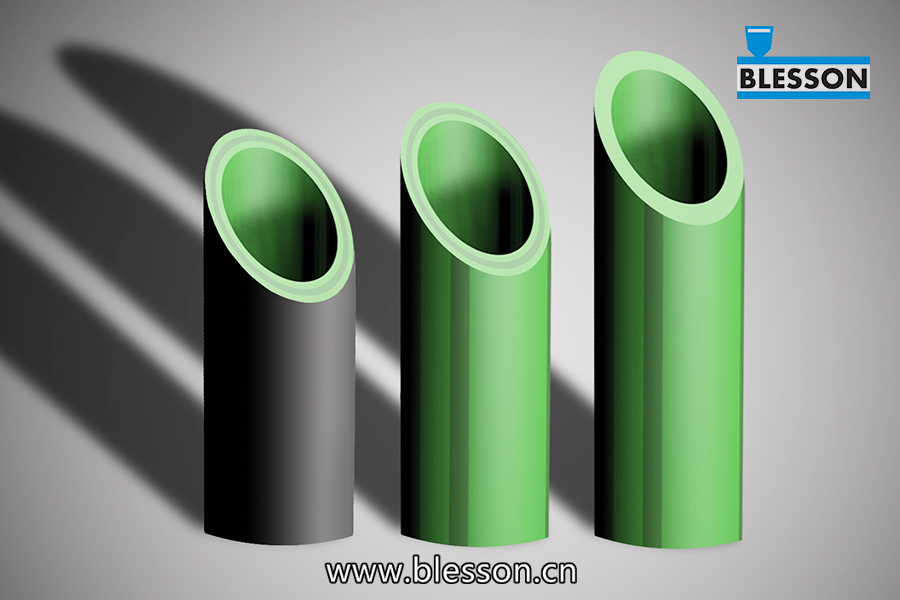

(1) PPR Hot and Cold Water Pipe

PPR hot and cold water pipes are mainly used in hot and cold drinking water piping systems, air conditioning systems, etc. PPR pipes are hygiene, non-toxic, recyclable, non-scaling, with the advantage of high wear resistance, corrosion resistance, sound insulation performance and long service life.

(2) PPR Fiberglass Multi-Layer Co-Extrusion Pipe

Since the linear expansion ratio of the PPR fiberglass multi-layer co-extrusion pipe is around 75% lower than that of the ordinary PPR pipe, it is not easy to deform when transporting hot water for a long time, and the transport efficiency will be around 20% higher. Therefore, in addition to the performance advantages of the single-layer PPR pipe, this multi-layer co-extrusion pipe has its outstanding advantages in the application of hot water transmission. Compared to PPR Aluminum composite pipe, it is easier to install and recycle.

(3) PPR Aluminum Composite Pipe

The PPR Aluminum Composite Pipe is composed of five layers, the outer layer and the inner layer are both PPR material, the middle layer is an Aluminum layer, and the glue layers are between the PPR layers and Aluminum layer. PPR Aluminum Composite Pipes are widely used in civil construction projects, solar energy, heating pipelines, central air-conditioning systems, drinking water delivery systems, chemicals and environmental protection. They are famous for good performance in high temperature working condition. Due to its characteristic of anti-ultraviolet, the pipe can guarantee the quality of pure water for long period of time.

Technical Highlights

● With the Siemens man-machine interface, our PPR pipe production line can record production data, which is convenient for users to analyze and manage production performance. The alarm function can remind mistake or failure that can help the operators to shoot the trouble quickly.

● The whole line is controlled by Siemens S7-1200 series PLC control system with 12-inch full-color touch screen. It is easy to operate and convenient to maintain.

● Guangdong Blesson Precision Machinery Co., Ltd can customize multi-layer co-extrusion pipe production line according to customer demand.

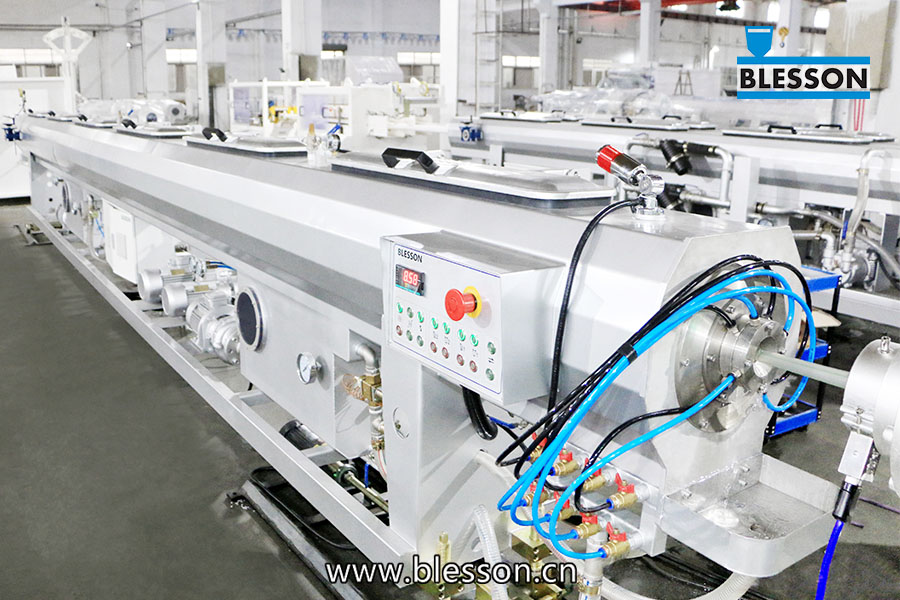

High-Efficiency Single Screw Extruder for PPR pipes

● According to the characteristics of PPR materials, Guangdong Blesson Precision Machinery Co., Ltd. provides high-efficiency single-screw extruders to guarantee stable performance and good plasticizing effect. In particular, our high-efficiency screw with a L/D ratio of 40 exclusively designed by Blesson can improve the plasticizing & dispersing effect during processing, and increase the production capacity of the extruder and the output of the production line. By increasing the residence time of the melt flow, the large L/D ratio single screw extruder can ensure sufficient melting time for higher quality and improve productivity. The optional gravimetric control system from iNOEX Germany can effectively save 3%-5% of raw material loss.

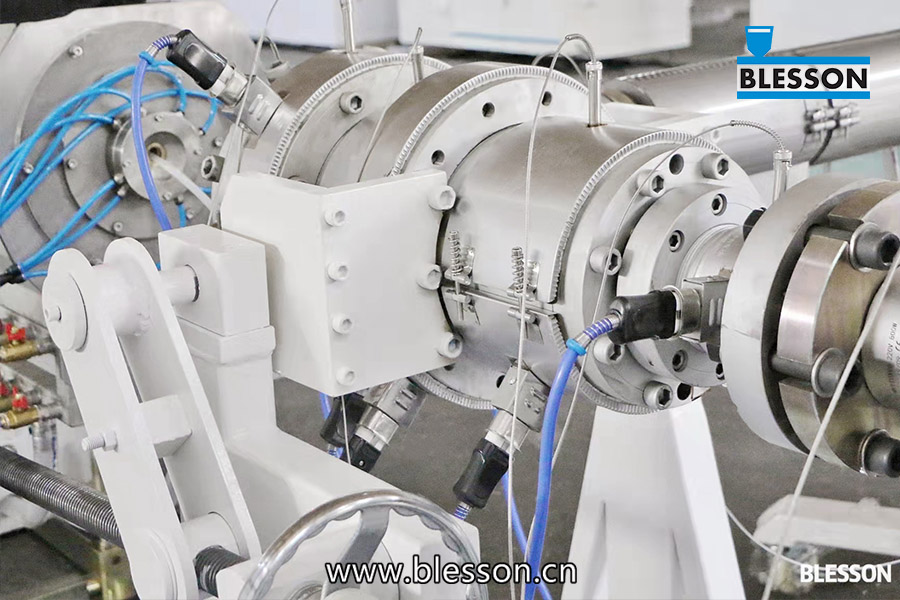

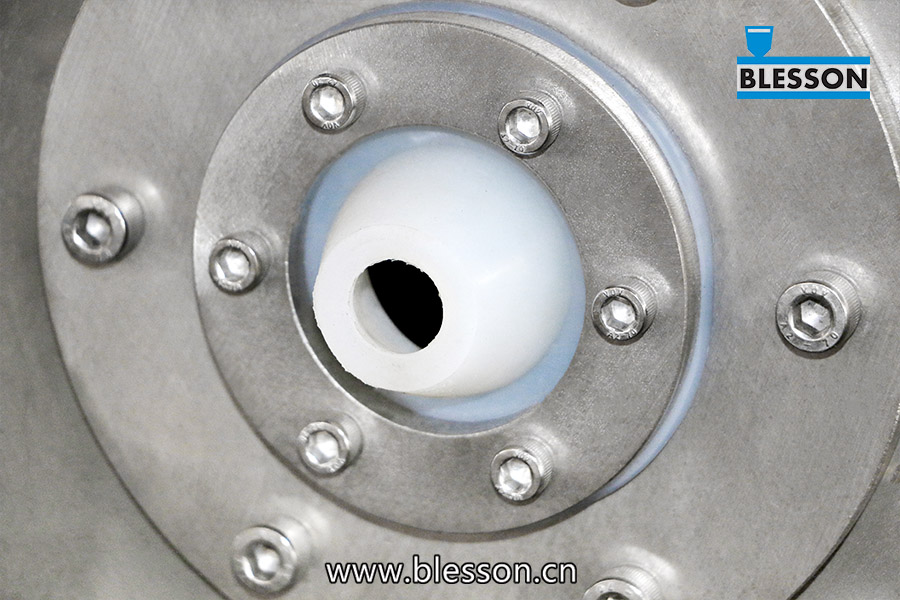

Professional PPR Pipe Extrusion Die, Multi-layer PPR pipe Co-extrusion Die

● The spiral die head of our PPR pipe extrusion die can lower the melt pressure and plasticizing temperature, and improve mixing performance and production stability with a wider processing range. With a strong structure, the spiral die is suitable for high-viscosity materials extrusion. The detachable design makes it easy to operate while changing pipe sizes. Blesson can customize various PPR pipe extrusion die for single-layer PPR pipe, double-layer PPR pipe, and multi-layer co-extrusion pipes with different thickness ratios.

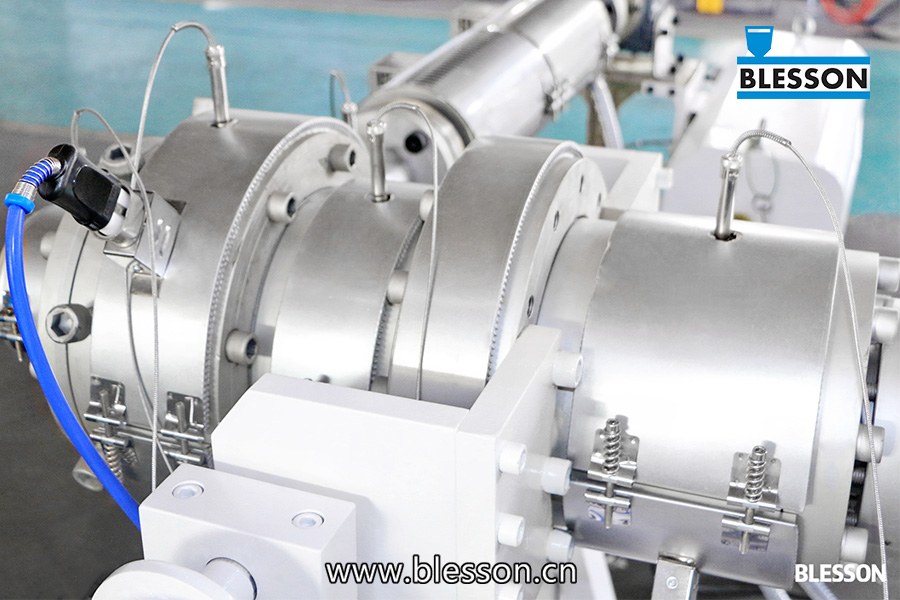

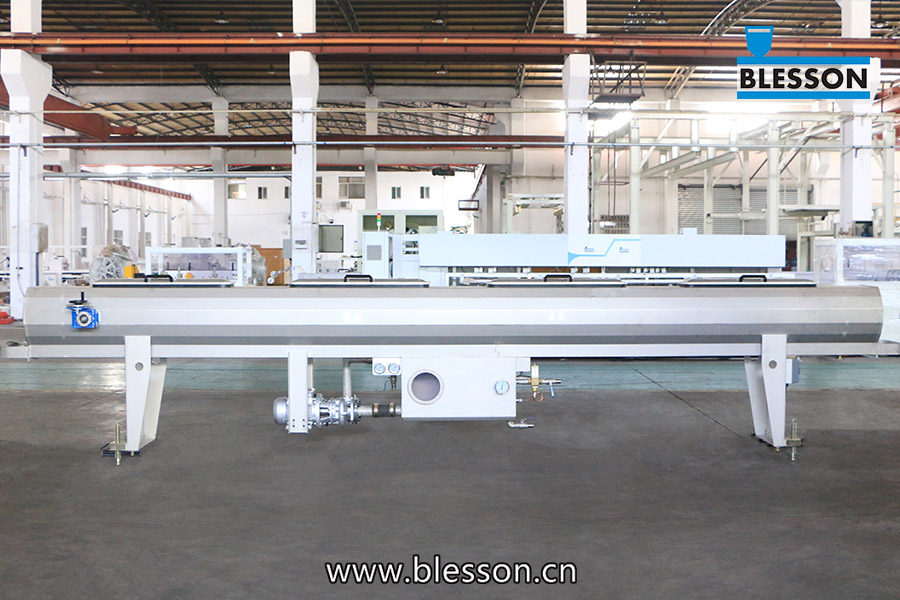

Energy Saving Vacuum Tank for PPR Pipe Extrusion

● The vacuum tank has a precise automatic control system for water level, water temperature and vacuum degree. Each vacuum pump is equipped with an inverter. The material of the vacuum tank body is 304 stainless steel, and the metal pipes and the pipe fittings (such as elbows) inside the tank are also made of 304 stainless steel, which has a long service life and good corrosion resistance. The funnel shape rubber sealing of the vacuum tank is made by injection instead of a piece of flat rubber sheet, which provides better sealing effect and longer life. The lid of vacuum tank for small diameter pipe is made of high-strength tempered glass, which is convenient for operator to observe the state of the pipe. The vacuum tank for larger pipes adopts a heavy cast aluminum lid to guarantee an excellent sealing effect. To ensure the high quality, we adopt famous brand for both the vacuum pump and the water pump for our vacuum tanks.

Upscale Stainless Steel Water Spray Tank for PPR Pipe Extrusion Line

● In order to achieve good processing performance and high toughness, our water spray tank for PPR pipe is made of mirror finished 304 stainless steel with a temperature resistance of 800°C. The built-in spraying nozzles assembled in reasonable layout secure a large spray angle for efficient cooling effect. The bypass pipeline filter with manual cleaning function is easy to maintain and purify the cooling water.

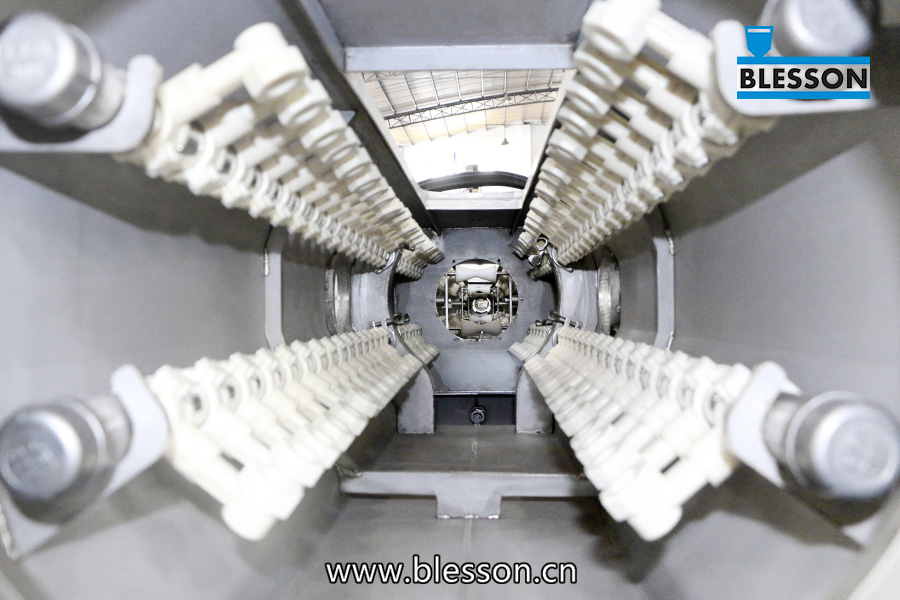

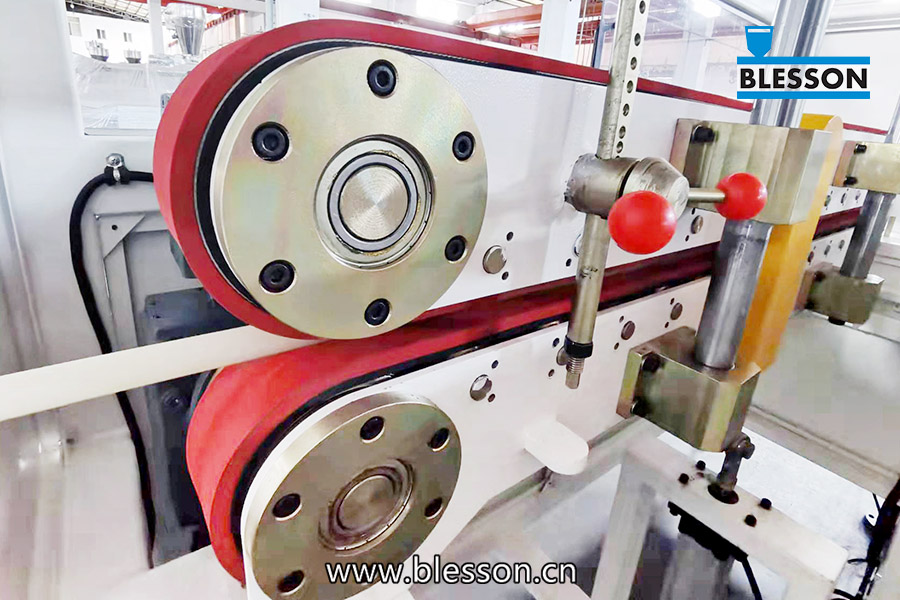

Powerful Haul-Off Unit of PPR Pipe Production Line

● According to the outer diameter of PPR pipe, our company provides different haul-off units to match different size. Each caterpillar of the haul off unit is controlled by independent permanent magnet synchronous motor for stable synchronization. And our double-belt haul-off unit is suitable for small diameter PPR pipes in high-speed production.

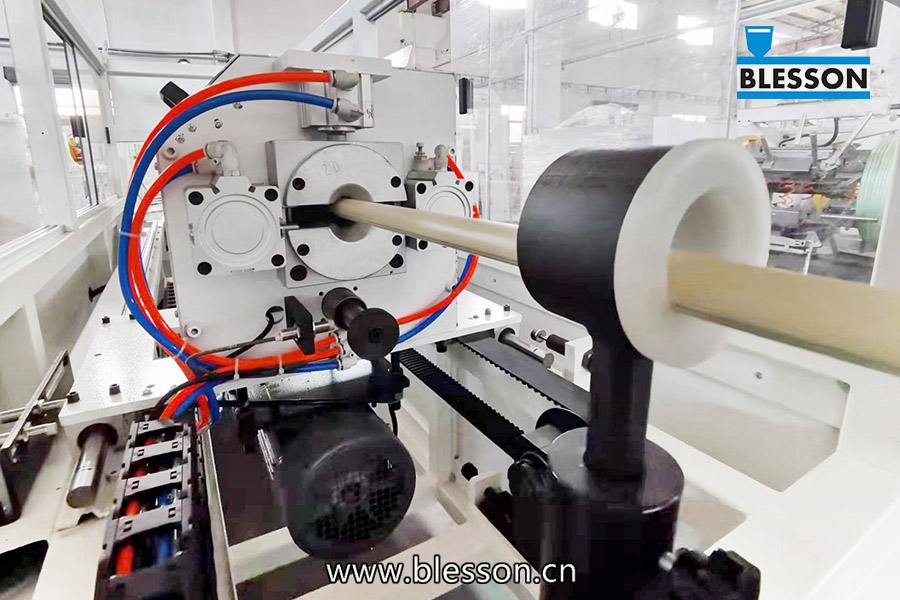

Capable Cutting Unit of PPR Pipe Production Line

● According to the speed of the production line, our company provides both flying knife cutting machine or swarfless cutting unit for different applications. The high-precision and low-noise swarfless cutting unit ensures a smooth and flat cutting section, while the flying knife cutting unit can adapt to a high production speed up to 30m/min, with a smart function to cut waste pipes automatically to improve production efficiency.

● According to the actual needs of customers, Guangdong Blesson Precision Machinery Co., Ltd. provides semi-automatic PPR pipe winding machine/coiler and online PPR pipe automatic strapping and packing machine for customers' option.

Product Model List

|

PPR Pipe Production Line |

||||||

|

Line Model |

Outer Diameter(mm) |

Extruder Model |

Max. Output(kg/h) |

Line Length(m) |

Installation Power(kw) |

Remarks |

|

BLS-28PPR |

28 |

BLD45-30 (Special for fiberglass) |

50 |

33 |

55 |

Fiberglass pipe |

|

BLS-32PPR(I) |

16-32 |

BLD40-34 BLD50-30 BLD30-30 |

25+80+6 |

30 |

120 |

Four-layer co-extrusion |

|

BLS-32PPR(II) |

16-32 |

BLD65-40 BLD50-40 |

300+250 |

50 |

272 |

Two-layer co-extrusion double pipe |

|

BLS-32PPR(III) |

16-32 |

BLD65-40 |

450 |

50 |

225 |

Double pipe |

|

BLS-32PPR(IIII) |

16-32 |

BLD75-33 BLD50-40B |

240+ 125×2 |

48 |

280 |

Three-layer co-extrusion |

|

BLS-63PPR(I) |

20-63 |

BLD65-34 BLD65-30 (玻纤专用) |

200+80 |

50 |

210 |

Fiberglass pipe |

|

BLS-63PPR(II) |

16-63 |

BLD65-40 BLD50-40 |

300+250 |

50 |

250 |

Two-layer co-extrusion double pipe |

|

BLS-63PPR(III) |

16-63 |

BLD65-40 |

450 |

50 |

200 |

Double pipe |

|

BLS-63PPR(IIII) |

20-63 |

BLD65-34 BLD50-34 BLD40-25 |

200+100+10 |

50 |

260 |

Aluminum-plastic stable composite pipe |

|

BLS-110PPR(I) |

20-110 |

BLD65-34 BLD65-30 (Special for fiberglass) |

200+100 |

50 |

245 |

Fiberglass pipe |

|

BLS-110PPR(II) |

75-110 |

BLD80-34 BLD50-34 |

300+100 |

56 |

380 |

Aluminum-plastic stable composite pipe |

|

BLS-110PPR(III) |

16-110 |

BLD50-40 |

330 |

55 |

170 |

|

|

BLS-110PPR(IIII) |

20-110 |

BLD80-34 |

300 |

60 |

215 |

PP-R pipe |

|

BLS-160PPR(I) |

32-160 |

BLD80-34 BLD65-30 (Special for fiberglass) |

300+100 |

51 |

290 |

Fiberglass pipe |

|

BLS-160PPR(II) |

32-160 |

BLD80-34 |

300 |

51 |

215 |

PP-R pipe |

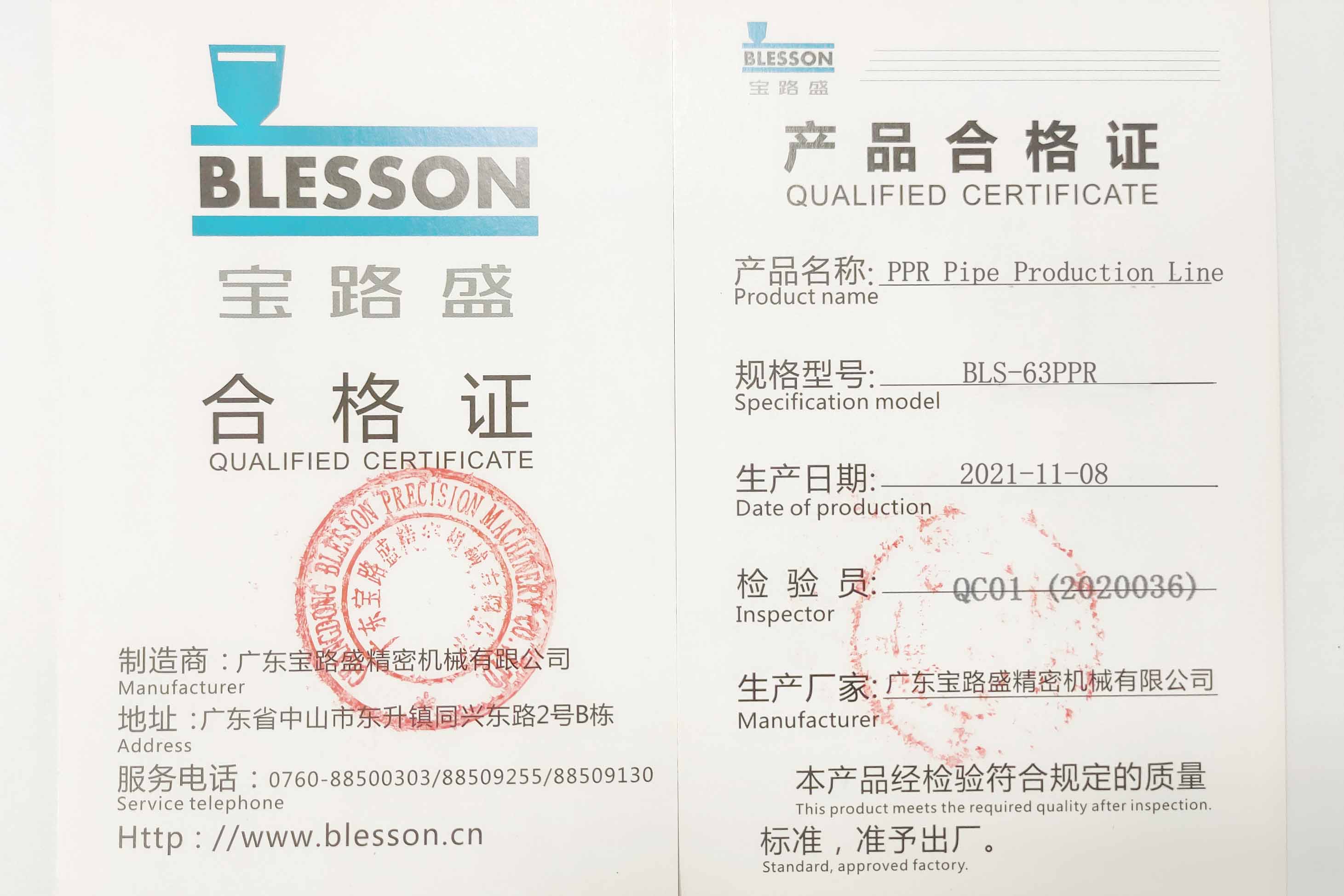

Warranty, Certificate Of Conformity

Guangdong Blesson Precision Machinery Co., Ltd. provides a one-year warranty service. During the use of the product, if you have any questions about the product, you can directly contact us for professional after-sales services.

Guangdong Blesson Precision Machinery Co., Ltd. provides product qualification certificates for each product sold, ensuring that each product has been inspected by professional technicians and debuggers.

Company Profile