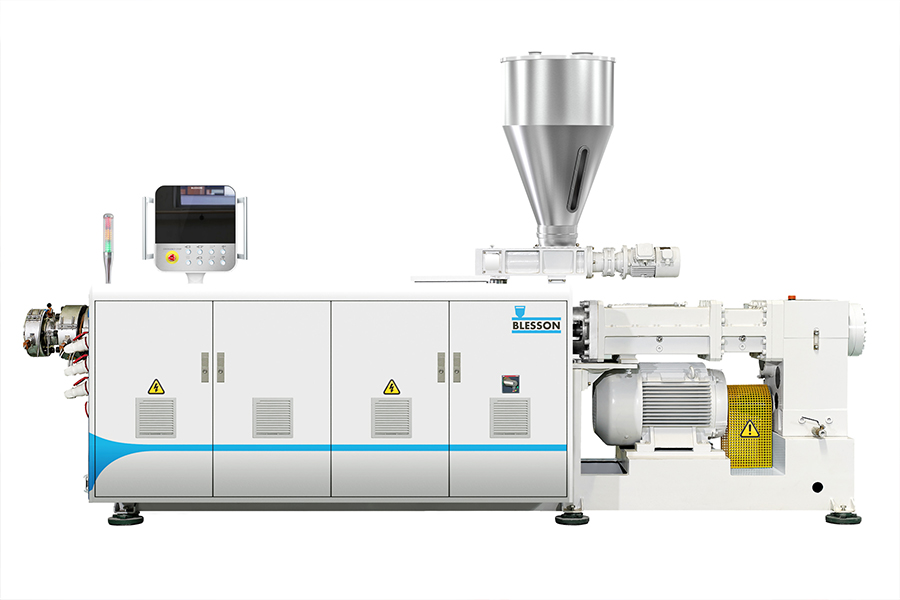

High Performance Parallel Twin Screw Extruder

Main technical features

1. High output, suitable for PVC powder plastic molding of various formulas.

2. Screw and barrel made of high-strength nitrided alloy steel (38CrMoALA), corrosion-resistant, and long service life.

3. Equipped with quantitative feeding system, frequency conversion speed control.

4. Unique screw design to ensure mixing and plasticizing effect, and achieve full exhaust.

5. Screw designs with different L/D ratios suitable for wide-range product production needs.

Extruder components:

Siemens motor

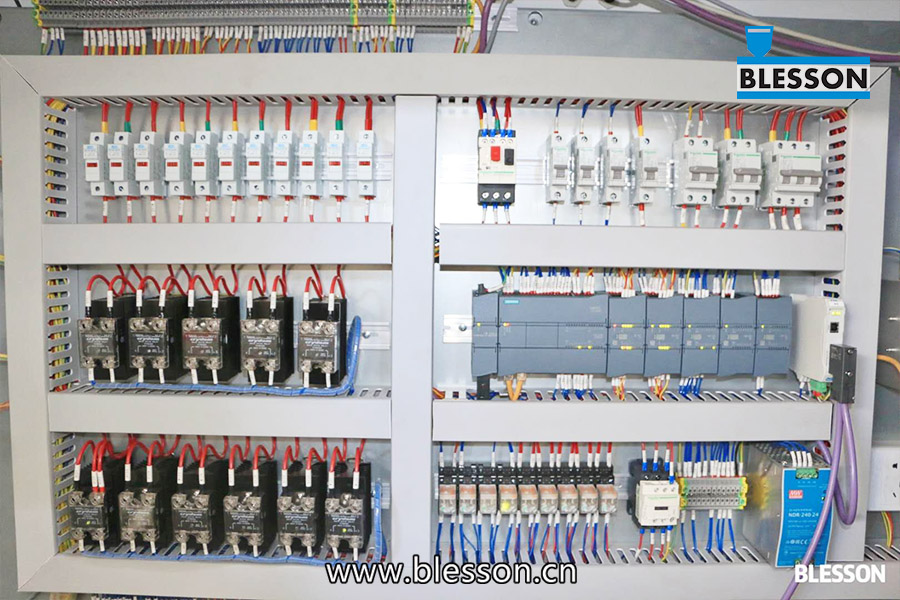

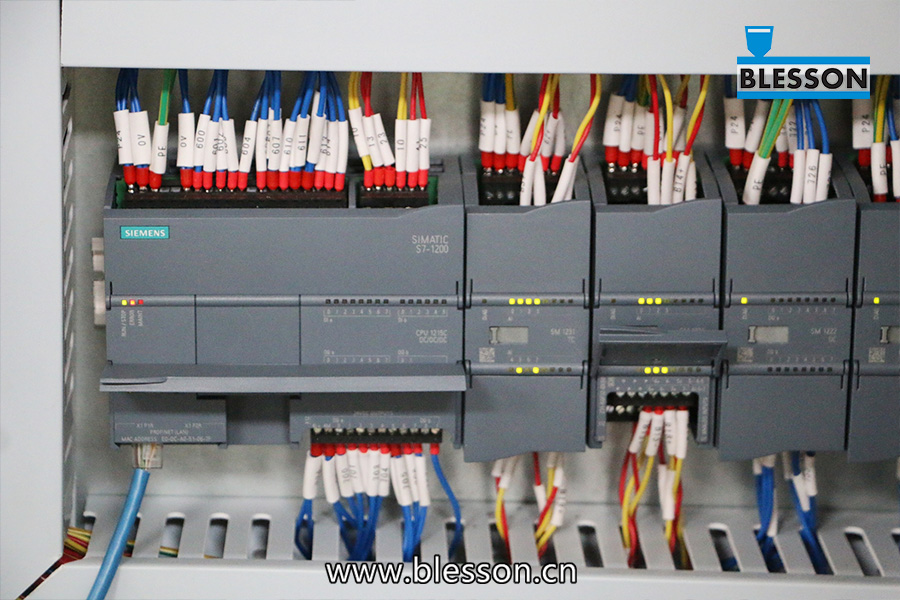

Siemens PLC control system

Heating and cooling

Well organized electric cabinet

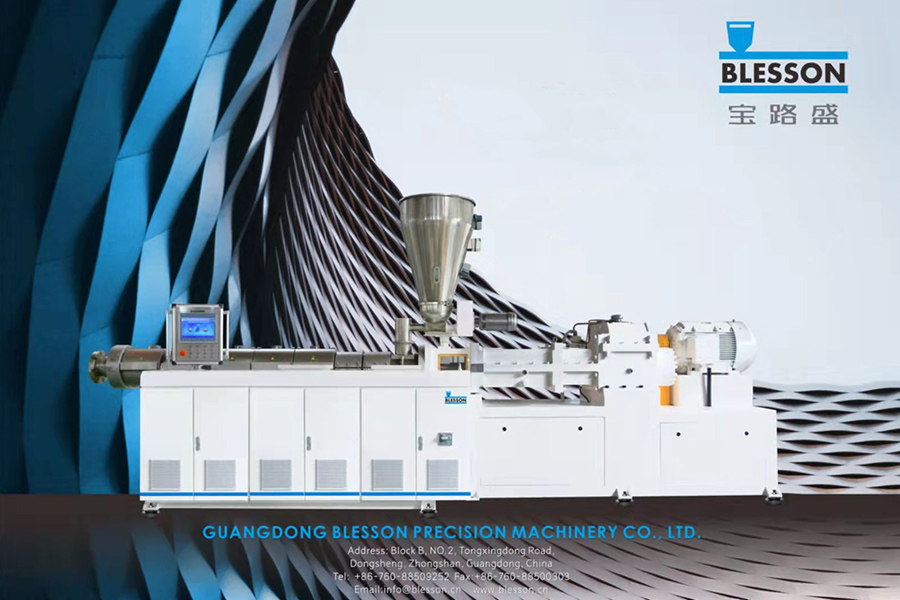

Product Applications

Parallel twin-screw extruders are widely used in plastic filling, blending, modification, reinforcement, granulation, etc., and also suitable for PVC water supply pressure pipe, PVC cable duct, conduit, trucking, PVC windows profiles that require large production capacity and low filling volume, as well as PVC pelletizing production line and PVC door panel production line.

Technical Highlights

● Due to professional and advanced design, our parallel twin screw extruder provides superb mixing and plasticizing effect, with stable material distribution and high conveying efficiency.

● It is highly automatic, intelligent, and easy for operation. Our parallel twin-screw extruder adopts world-wide famous electrical components and intelligent man-machine interface. Together with the clear structure of its multi-functional module and reasonable safety protection measures, the extruder can truly reflect the operation status in a highly sensitive and accurate way.

● Low-voltage electrical components are selected from world-wide famous suppliers, such as Siemens, ABB, Schneider, etc., which assure the system with high quality and various versatility. It is also convenient for after-sales maintenance as the users can easily get the access of the components for replacement from the local office of those big component suppliers.

● The corrosion-resistant screw and barrel are made of high-strength alloy steel (38CrMoALA) with high quality nitriding layer treatment, which improves its service life.

● The professional and reasonable screw design ensures the mixing and plasticizing effect, as well as the air exhaust sufficiency.

● Blesson's parallel twin-screw extruders with different diameters and L/D ratios can meet the requirement of various PVC extrusion products.

● Equipped with a permanent magnet synchronous motor, Blesson's parallel twin-screw extruders can run smoothly with large transmission torque, as well as high efficiency and low noise.

● The motor is equipped with an efficient air-cooling device to prevent the motor from overheating.

● The cast aluminum or ceramic heaters provides even and efficient heating, with high quality temperature sensors to guarantee the accurate temperature control.

● The selected parallel twin-screw gearbox is manufactured by precise manufacturing processes. The strengthened surface treatment of the gears results in high torque, low noise and long life cycle.

● According to the customer's demand for color switching, the online color mixer with weighing function can be selected.

● The parallel twin-screw extruder is controlled by Siemens S7-1200 series PLC, with data acquisition and data analysis functions.

Guangdong Blesson Precision Machinery Co., Ltd. continuously optimizes and innovates in the design of screw and barrel in order to fulfill the needs of different customers' applications. Guangdong Blesson Precision Machinery Co., Ltd. has successfully designed and manufactured special screws for various products with different formulas, including films, panels, profiles, etc.

The parallel twin-screw extruder system developed by Guangdong Blesson Precision Machinery Co., Ltd. has a unique core competitiveness. The weighing device can ensure the consistency of the materials entering the extruder. During the same period of time, the input material and extrusion volume remain unchanged with stable pressure.

Model List

|

Model |

Screw Diameter (mm) |

L/D |

Max. Speed (rpm) |

Motor Power (kW) |

Max. Output |

|

BLP75-26 |

75 |

26 |

47 |

37 |

350 |

|

BLP90-26 |

90 |

26 |

45 |

55 |

600 |

|

BLP108-26 |

108 |

26 |

45 |

90 |

800 |

|

BLP130-26 |

130 |

26 |

45 |

132 |

1100 |

|

BLP114-26 |

114 |

26 |

45 |

90 |

900 |

|

BLP90-28(I) |

93 |

28 |

40 |

75 |

600 |

|

BLP90-28(II) |

93 |

28 |

26 |

55 |

450 |

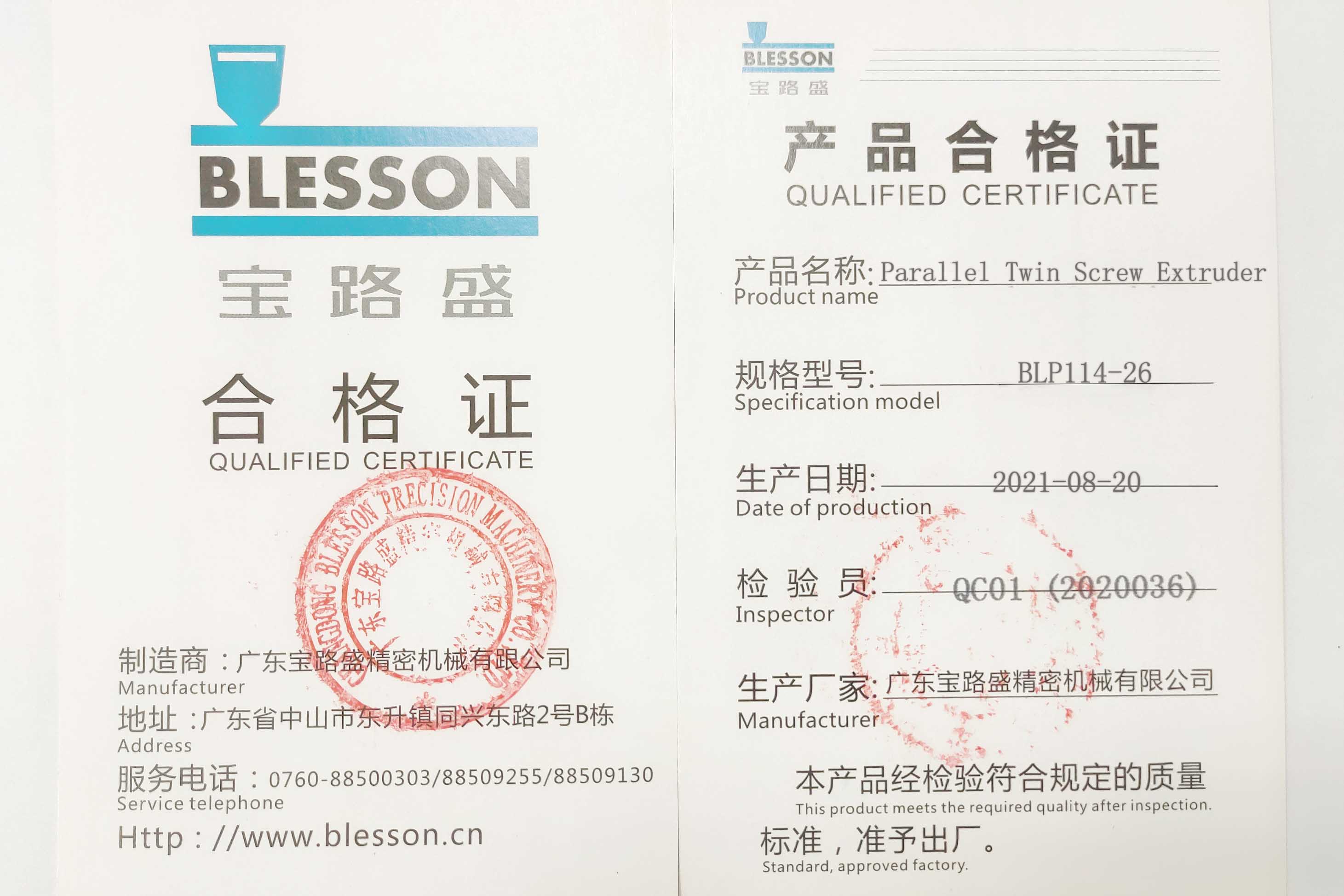

Warranty, Certificate Of Conformity

Guangdong Blesson Precision Machinery Co., Ltd. provides a one-year warranty service. During the use of the product, if you have any questions about the product, you can directly contact us for professional after-sales services.

Guangdong Blesson Precision Machinery Co., Ltd. provides product qualification certificates for each product sold, ensuring that each product has been inspected by professional technicians and debuggers.

Company Profile