PVC Four-pipe Production Line

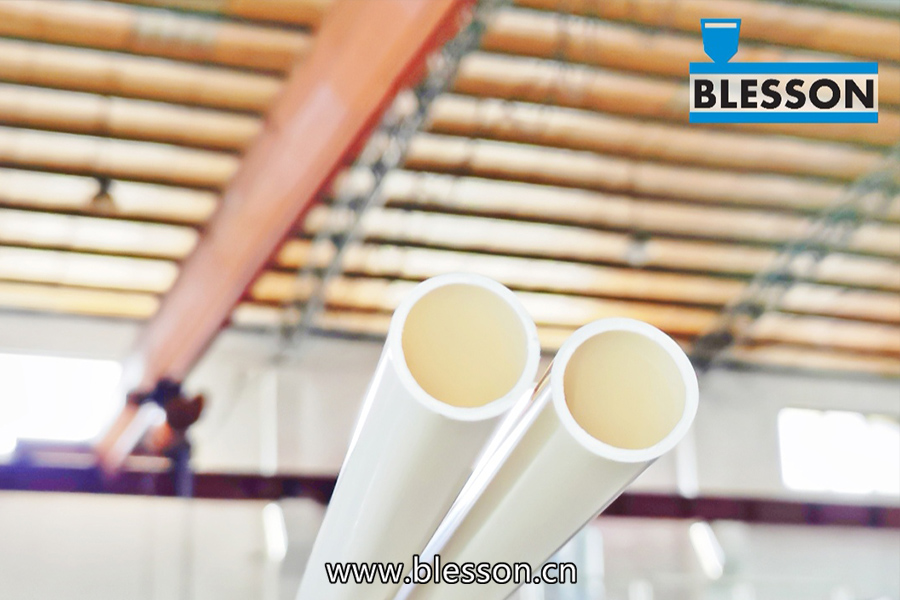

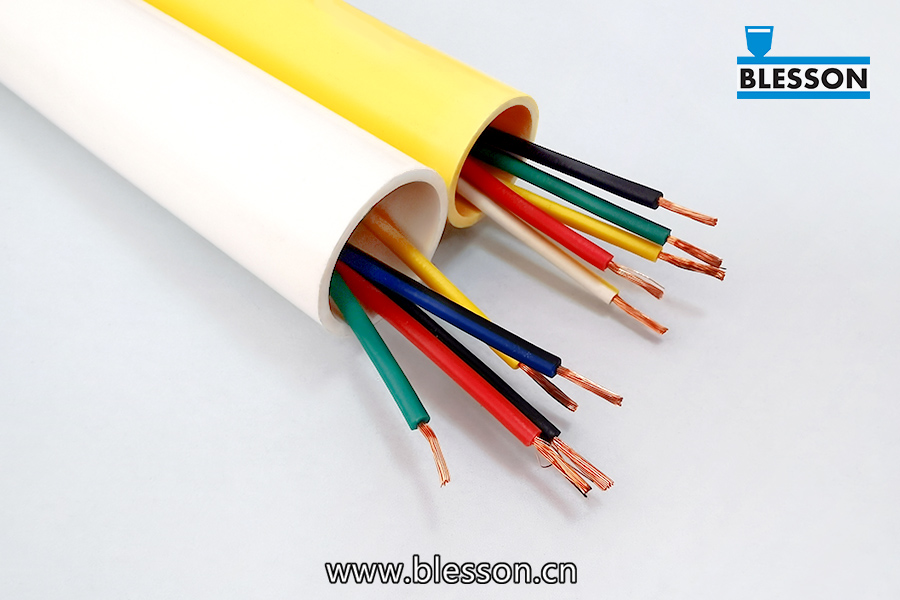

Product Applications

These pvc pipes is with excellent insulation performance, strong impact resistance, good resistance to fire, moisture, acid and alkali, suitable for electrical casing, cable protection, water drainage, etc.

Product Technology Highlights

● The four-strand PVC pipe production line produced by Guangdong Blesson Precision Machinery Co., Ltd. adopts a high-output and efficient conical twin-screw extruder, a professionally designed extrusion die, a powerful cooling calibration unit, and a haul-off and cutting combination unit. It features stable extrusion, comprehensive configuration, mature and leading design, and high production efficiency.

● The electronic components of Blesson four-strand PVC pipe production line are from world-wide famous brand like Siemens and ABB, which ensures the stability of the production line and prolongs its service life.

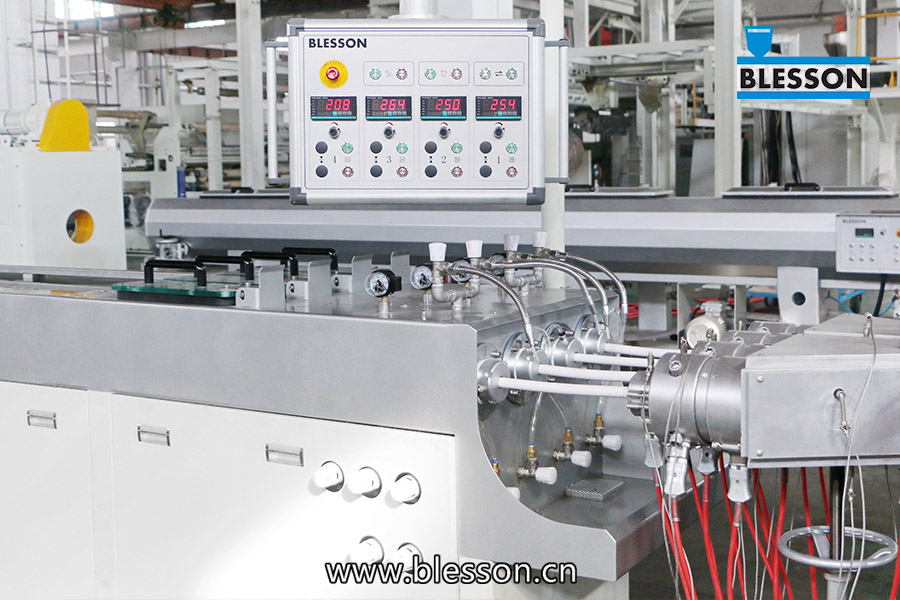

● Users can choose manual control or Siemens S7-1200 series PLC control according to actual needs. The manual control system is controlled by independent thermometers, which is simple to operate and easy for maintenance. The Siemens S7-1200 series PLC control system is equipped with a 12-inch touchable screen with frequently used manual shortcut buttons that can be operated with heat-resistant gloves on. Customers will get benefits from its powerful function, strong practicability, and user-friendly design.

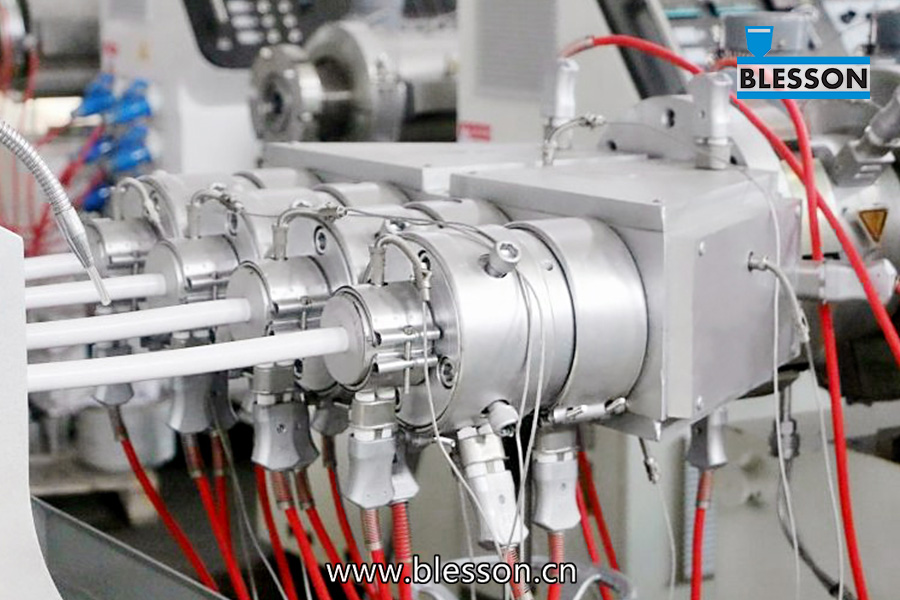

Extruder

● Blesson four-strand PVC pipe production line is equipped with energy-saving and high-efficient conical twin screw extruder. The extruder can plasticized the material at lower temperature with stable performance. With a quantitative feeding system, variable frequency speed regulation, the extruder can fulfill different needs of output requirements.

● The scientific and reasonable design of the screws can adapt various PVC formulas to meet different needs of our customers. Made of nitrided alloy steel (38CrMoALA), and with nitriding and polish treatment, the screw ensures the plasticizing effect with high strength and wearing resistance.

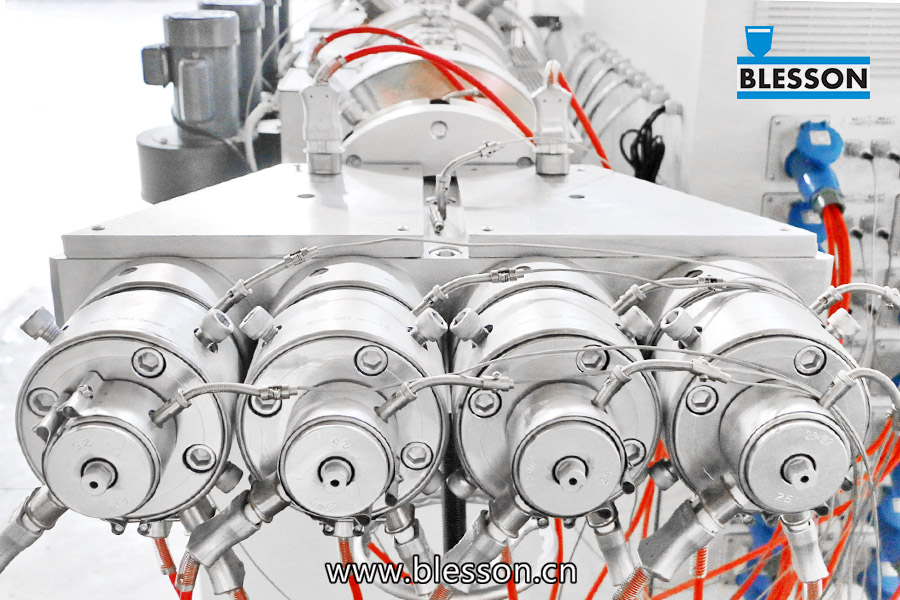

Extrusion Die

● The four-strand pvc pipe extrusion die designed by Blesson has a smooth flow channel to ensure uniform extrusion of the material along the flow channel. To avoid overheating and decomposition of the material, our design can reduce the residence time of the material and improve the plasticizing and blending effect. Our PVC four pipe extrusion die transfers the heat evenly, which results a good molding effect. Precise machining can effectively avoid any leakage. The bushes, pins and calibrators of the extrusion die can be replaced easily for different sizes while sharing the same die head and distributor.

Calibration Table

● The calibration table is made of SUS304 stainless steel with superb corrosion resistance, firmness and long service life.

● It is easy to adjust the vacuum setting for each independent workstation..

● The efficient water immersion cooling ensures the quality of the pipe under high production speed.

● The movable control panel of the calibration table provides convenience for the commissioning, startup and maintenance of the production line.

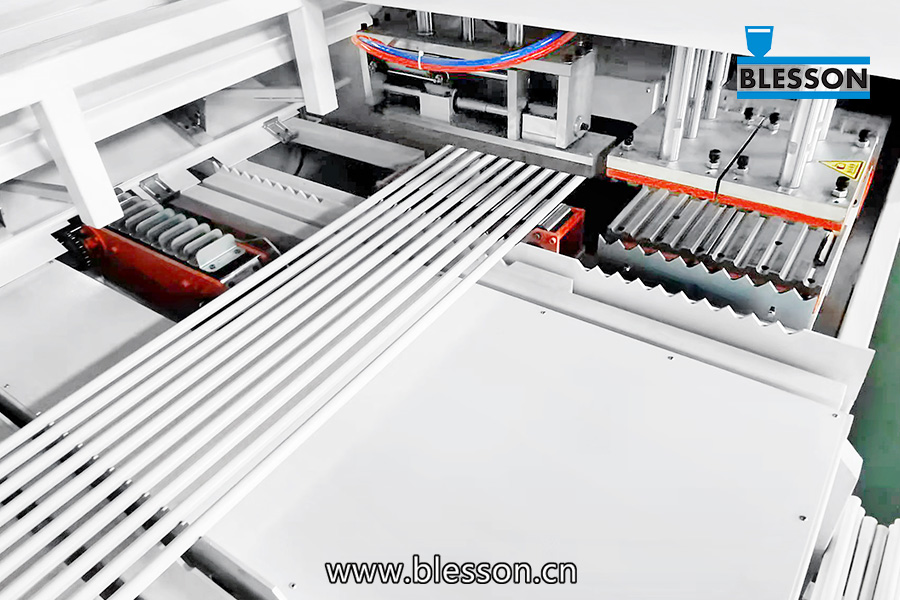

Haul-off & Cutting Combination Unit

● In order to assure prompt cutting dynamic response during high speed production, the swarf-free cutting is directly driven by DD motor instead of traditional AC motor. Without the burden of the weight of traditional motor, this haul-off & cutting combination unit can ensure smooth cutting edge and precise cutting length for both thick pipe and thin pipe in high speed.

● To guarantee the synchronization and stability, the haul-off unit adopts high quality permanent magnet synchronous motor and speed reducer.

● The whole unit is fully enclosed to ensure the safety for the operators.

● The Siemens PLC touch screen control with frequently used mechanical buttons on the control panel provide a friendly and easy control and setting mode.

● According to customer needs, it can be equipped with a automatic belling machine or an automatic bundling and packaging machine.

Product Model List

|

PVC Four Pipe Production Line |

|||||

|

Line Model |

Diameter Range(mm) |

Extruder Model |

Max. Output(kg/h) |

Length of Line(m) |

Total Installation Power(kW) |

|

BLS-32PVC |

16-32 |

BLE65-132 |

280 |

20 |

90 |

|

BLS-32PVC |

16-32 |

BLE80-156 |

480 |

20 |

150 |

|

BLS-32PVC |

16-32 |

BLE65-132G |

450 |

20 |

100 |

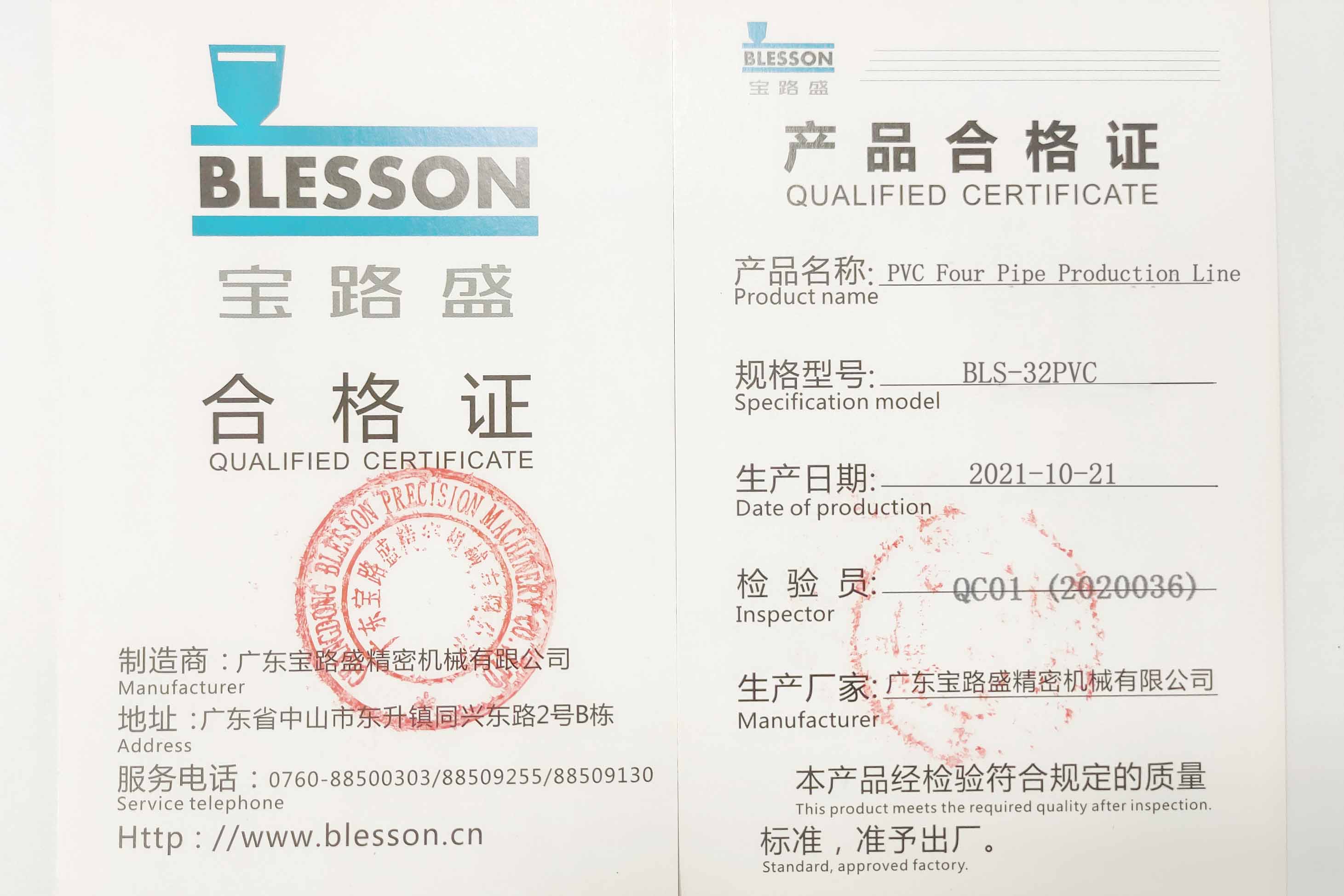

Warranty, Certificate Of Conformity

Guangdong Blesson Precision Machinery Co., Ltd. provides a one-year warranty service. During the use of the product, if you have any questions about the product, you can directly contact us for professional after-sales services.

Guangdong Blesson Precision Machinery Co., Ltd. provides product qualification certificates for each product sold, ensuring that each product has been inspected by professional technicians and debuggers.

Company Profile