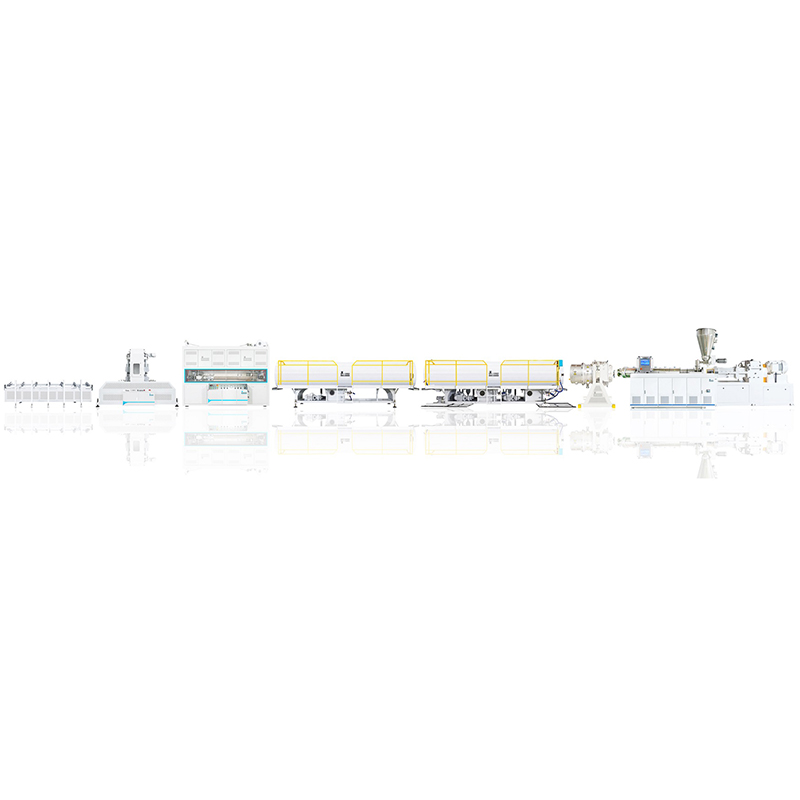

High Productivity PVC Pipe Production Line

Product Applications

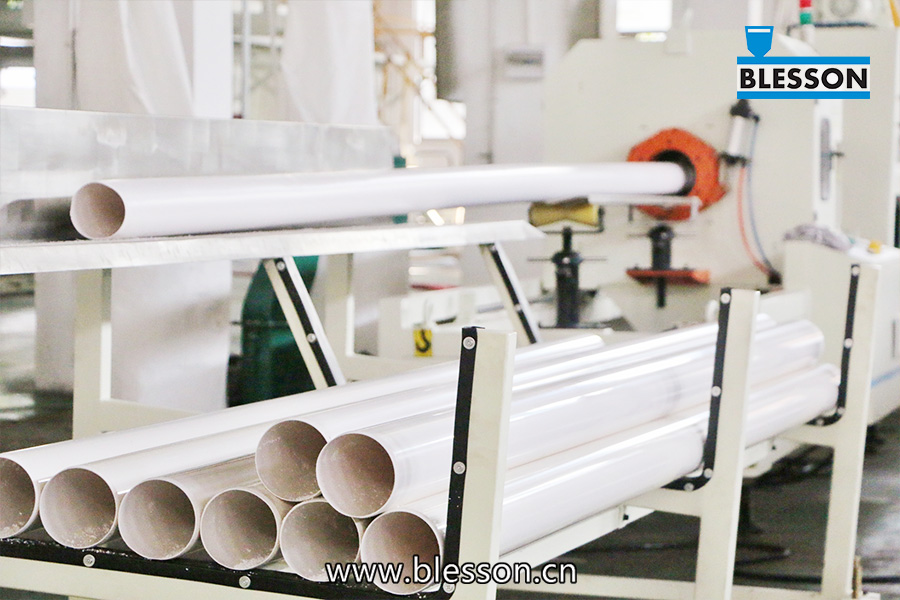

At present, our PVC pipe production lines can be used to produce PVC-U water supply pipes, PVC-U drainage pipes, PVC-U radially reinforced pipes, PVC-U double-wall corrugated pipes, and PVC-U spiral muffler pipes, etc.

(1) PVC-U water supply pipe

PVC-U water supply pipes can be used in building indoor water supply systems, urban water supply piping systems, garden irrigation and sewer piping systems, etc. It has many advantages, such as chemical resistance, acid and alkali resistance, pressure resistance, pollution-free, smooth inner wall, and no impact on water quality, and other advantages.

(2) PVC-U drainage pipe

As the most used plastic pipe in drainage engineering, PVC-U drainage pipe has the advantages of simple construction, convenient operation, good corrosion resistance, long service life and high pipe safety factor. It has been widely used in various industries, including building drainage system, sewage system, urban road drainage system and chemical drainage system, etc.

(3) PVC power cable duct

PVC power cable duct is mainly used in telecommunications, cable protection and communication pipelines of highways, etc. It has the advantages of strong corrosion resistance, good heat resistance, light weight, resistance to aging and convenient installation.

(4) PVC-U radially reinforced pipe

As a new type of PVC-U pipe, PVC-U radially reinforced pipe is characterized by reducing the wall thickness and yet improving the pressure resistance. The outer wall of the pipe is provided with radial reinforcing ribs to improve the stiffness and compressive strength of the pipe, and is suitable for the drainage and sewage system in municipal engineering. The PVC-U radially reinforced pipe has the advantages of light weight, convenient transportation, corrosion resistance, good anti-leakage performance, smooth inner wall and long service life.

(5) PVC-U spiral muffler pipe

The PVC-U spiral muffler pipe adopts a unique spiral structure, which reduces the impact on the inner wall of the pipe during drainage and reduces noise. It can be applied to the drainage system of construction projects and urban drainage systems. It has large drainage capacity, high pipe strength, and convenient installation.

(6) PVC-C pipe

PVC-C pipes are widely used in civil and commercial cold and hot water pipe systems and direct drinking water systems. They can be used for the transportation of hot water, corrosion-resistant liquids and gases. They can be divided into PVC-C fire pipes and PVC-C cold and hot water pipes. PVC-C fire pipes have the advantages of heat resistance, ignition resistance and energy saving. PVC-C hot and cold water pipes have the advantages of corrosion resistance, strong sulfuric acid resistance, strong alkali resistance, bacteria not easy to multiply, fast installation, and environmental protection.

Technical Highlights

● The PVC pipe production line produced by Guangdong Blesson Precision Machinery Co., Ltd. has reasonable configuration, mature technology and human-based design. The economic and practicality of our pipe production line is recognized by our customers, and the cost performance is higher than the average level in the industry.

● The high degree of automation design can effectively save the cost of human resources, ensure the easy operation of the pipe production line, and have high-precision control and excellent synchronization.

Extruder

● According to customer preference, our PVC pipe production line can be equipped with conical twin-screw extruder or parallel twin-screw extruder. The extruder is equipped with a quantitative feeding system, which can be controlled by frequency conversion and speed control, and is equipped with fault alarm and overload protection functions. It has the advantages of large extrusion volume, small shear rate and difficult decomposition of materials.

● The screw design of the twin-screw extruder is scientific and reasonable. The screw has undergone fine treatments such as nitriding and high-frequency quenching to ensure good mixing and plasticizing effects, and full exhaust. The core temperature control device equipped with the screw can better control the processing temperature of the material.

Mold

● Blesson PVC pipe mold can produce PVC pipes with various diameters from 16mm to 1000mm.

● The PVC pipe mold designed by Blesson adopts a shunt shuttle bracket type die, with a optimal runner design, and an easy-to-disassemble mold structure to ensure the plasticization effect of PVC, improve the flow performance of the material, and the user can change the mold and adjust the center height and horizontal angle of the mold according to the actual production requirements.

● In terms of mold manufacturing process, our molds are made of high-quality mold steel, which are manufactured through forging, rough machining, quenching and tempering treatment, runner surface rough polishing and fine polishing, mechanical finishing and hardening and anti-corrosion treatment. The standardized manufacturing process ensures that the mold has good material stability and wear resistance and corrosion resistance. The plastic also has good fluidity in the mold.

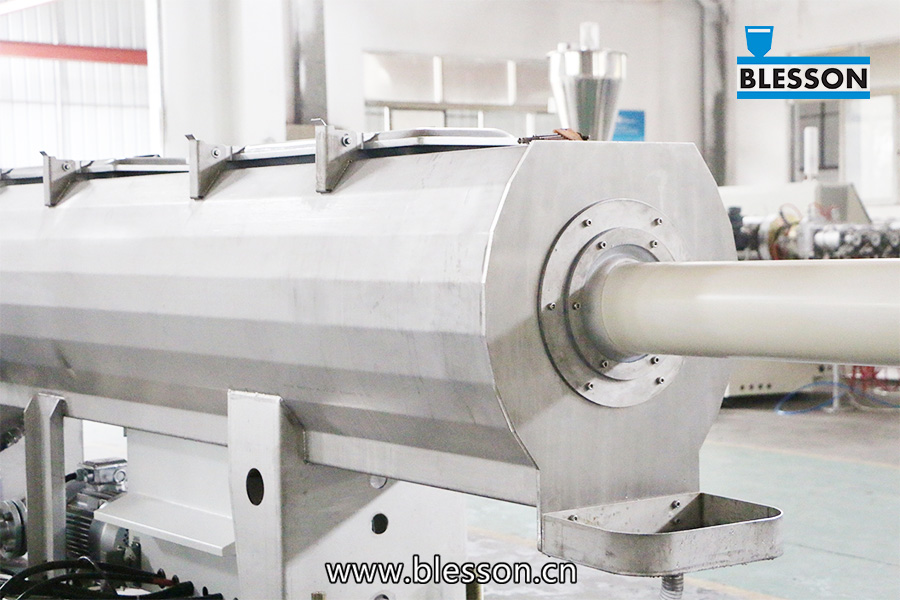

Vacuum tank

● The vacuum tank adopts the most advanced water supply and drainage integrated structure to ensure that the pipeline is clear, which greatly reduces the difficulty and time of installation and maintenance. The vacuum tank body, pipelines, pipeline fittings, etc. are all made of high-quality SUS304 stainless steel, which significantly improves the anti-corrosion durability. The heavy cast aluminum cover and three-layer rubber ring on the vacuum tank ensure better sealing. The high-precision water ring vacuum pump ensures a stable and effective shaping of products. The tightly arranged sprinklers and stable water pressure improve the speed and uniformity of pipe cooling. Precise water level control and water temperature control further improve the quality of PVC pipe cooling and shaping. The large-capacity water filter and backup bypass can effectively clean impurities in the cooling water, and can quickly clean the filter without stopping the machine.

Haul-off unit

● According to the requirements of different pipe sizes, our company has developed a variety of haul-off units to adapt to the corresponding production line requirements. From belt hauling for small pipes, two-caterpillar hauling, three-caterpillar hauling, cross four-caterpillar hauling, etc., to twelve-caterpillar hauling, every type is available.

● Each caterpillar is equipped with an independent servo motor drive, and the synchronization of the hauling speed of each caterpillar is ensured by a digital controller. The uniquely designed caterpillar rubber blocks improve the friction in the hauling process, effectively reduce the slipping problems, and are easy to install and replace.

Cutting unit

● For PVC pipes with small and medium diameters, our company has developed a chipless cutting machine; the multi-point clamping design for small-and-medium-diameter pipes can be automatically and steplessly adjusted without changing the fixture, reducing the time of pipe size changeover during production. For pipes with medium and large pipe diameters, our company uses planetary cutting units with different cutting ranges to meet the needs of production. Our cutting machine adopts high-quality hydraulic system to ensure stable driving force. The clamping stability, rotation accuracy and the synchronization of the cutting machine's forward and backward movement ensure the smooth cut and uniform chamfering of the PVC pipe.

Socketing machine

● According to the actual application of different PVC pipes, the socketing machine produced by our company can perform U-shaped socketing, straight socketing and rectangular socketing. The socketing machine can double-heat the inner and outer layers of the PVC pipe to ensure the accuracy of the socketing size. The socketing machine adopts a hydraulic external pressure forming method to ensure that the shape of the PVC pipe after the socketing is consistent with the shape of the socketing mold, and the quality of the PVC pipe is improved.

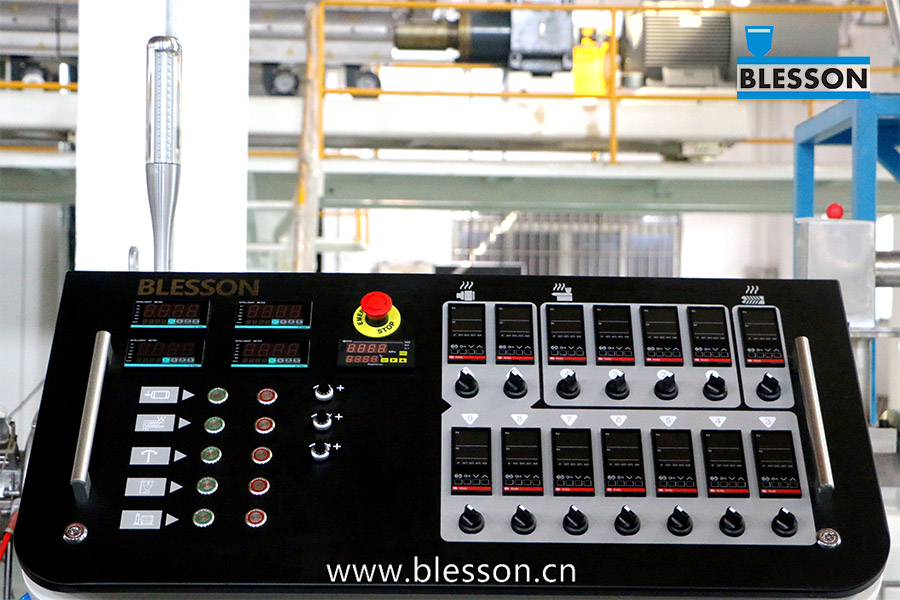

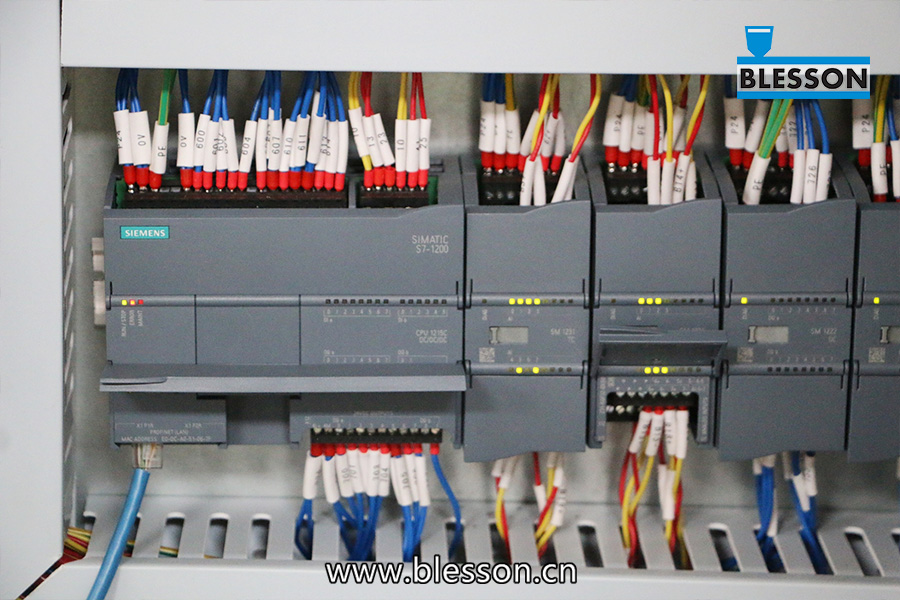

Control system

● The circuit design of multiple protections ensures that the equipment is not damaged under abnormal conditions. Our company uses well-known brands of electrical components, such as Siemens, ABB and Schneider, etc., to ensure the stability and safety of the production line, and improve the convenience of after-sales replacement of electrical parts.

● Our PVC pipe production line can choose manual control mode or PLC control mode.

● The manual control method is controlled by OMRON or TOKY temperature controller, which is convenient for after-sales maintenance.

● The PLC control mode uses the integrated technology of Siemens S7-1200 series PLC to perform calculation, measurement, temperature control and motion control of the extrusion system, realize the automation tasks of the PVC pipe production line, improve the automation level of the production line, and reduce the cost of human resources.

● The touch-screen Siemens man-machine interface can record formula data and production data, which is convenient for users to better manage the operation of the production line. At the same time, the user can quickly determine the cause of the fault and eliminate the fault through the alarm function.

● Manual buttonsare set under the PLC control panel, which can quickly adjust common functions such as extruder speed, hauling speed and synchronization without taking off the heat-resistant gloves.

● Through the PROFIBUS module of Siemens PLC, the information of each equipment can be integrated, and the equipment can be monitored and controlled more easily through fieldbus control, and the operation of the production line is more stable.

Model List

|

PVC Pipe Production Line |

|||||

|

Line Model |

Diameter Range (mm) |

Extruder Model |

Max. Output (kg/h) |

Length of Line (m) |

Total Installation Power (kW) |

|

BLS-63 PVC |

16-63 |

BLE55-120 |

200 |

20 |

95 |

|

BLS-63CPVC |

16-63 |

BLE65-132 |

180 |

28 |

105 |

|

BLS-110 PVC(I) |

63-110 |

BLE80-156 |

450 |

27 |

180 |

|

BLS-110 PVC(II) |

20-110 |

BLE65-132 |

280 |

27 |

110 |

|

BLS-110 PVC(III) |

63-110 |

BLE65-132G |

450 |

28 |

100 |

|

BLS-160 PVC(I) |

63-160 |

BLE80-156 |

450 |

30 |

175 |

|

BLS-160 PVC(II) |

40-160 |

BLE65-132 |

280 |

27 |

125 |

|

BLS-160 PVC(III) |

110-160 |

BLE92-188 |

850 |

40 |

245 |

|

BLS-160 PVC(IIII) |

75-160 |

BLE65-132 |

280 |

27 |

125 |

|

BLS-160 PVC(IIIII) |

40-160 |

BLP75-28 |

350 |

27 |

95 |

|

BLS- 250 PVC(I) |

63-250 |

BLE80-156 |

450 |

34 |

195 |

|

BLS- 250 PVC(II) |

63-250 |

BLE65-132 |

280 |

34 |

145 |

|

BLS-250 PVC(III) |

110-250 |

BLE-92-188 |

850 |

45 |

265 |

|

BLS-250 PVC(IIII) |

50-250 |

BLE65-132 |

280 |

29 |

210 |

|

BLS-315(I) |

63-315 |

BLE80-156 |

450 |

34 |

230 |

|

BLS-250 PVC(IIIII) |

110-250 |

BLP90-28 |

600 |

44 |

160 |

|

BLS-250 PVC(IIIIII) |

63-250 |

BLE65-132G |

450 |

35 |

100 |

|

BLS-315 PVC(II) |

63-315 |

BLE65-132G |

450 |

35 |

120 |

|

BLS-400 PVC(I) |

110-400 |

BLE92-188 |

850 |

45 |

290 |

|

BLS-400 PVC(II) |

180-400 |

BLE95-191 |

1050 |

45 |

315 |

|

BLS-400 PVC(III) |

180-400 |

BLP114-26 |

800 |

50 |

250 |

|

BLS-630 PVC(I) |

160-630 |

BLE92-188 |

850 |

45 |

330 |

|

BLS-630 PVC(II) |

160-630 |

BLP114-26 |

900 |

48 |

510 |

|

BLS-800 PVC(I) |

280-800 |

BLE95-191 |

1050 |

46 |

380 |

|

BLS-800 PVC(II) |

280-800 |

BLP130-26 |

1100 |

42 |

280 |

|

BLS-1000 PVC |

630-1000 |

BLE95-191 |

1050 |

52 |

540 |

Warranty, Certificate Of Conformity

Guangdong Blesson Precision Machinery Co., Ltd. provides a one-year warranty service. During the use of the product, if you have any questions about the product, you can directly contact us for professional after-sales services.

Guangdong Blesson Precision Machinery Co., Ltd. provides product qualification certificates for each product sold, ensuring that each product has been inspected by professional technicians and debuggers.

Company Profile