PVC Trunking, PVC Door and Window Profiles, PVC Gutter Production Line, Customized PVC Profile Extrusion Machine

Product Application

PVC profiles are widely used in the construction industry, such as PVC plastic door and window profiles, PVC trunking, PVC hollow ceiling wall panels, PVC gutter, furniture profiles, vinyl fence, door and door flames, noise barriers etc.

(1) PVC industrial trunking

PVC industrial trunking is durable and convenient to used to cover electrical equipment as well as having excellent fire resistance and insulation. PVC industrial trunking can also protect the electrical cables and reduce the hidden danger of electricity leakage, which helps to create a safer environment for the building.

(2) PVC gutter to drain the rainwater in the roof

The PVC gutter plays an important role of rapid drainage in the roofing system,which is generally set at the entrance of rainwater pipe to protect the roof by effectively blocking large debris.

(3) PVC plastic door and window profiles

Due to the superior weather resistance, thermal insulation as well as easy installation, PVC plastic door and window profiles have large-scale application in construction. What’s more, with the development of increasing requirements for the quality and style of PVC doors and windows, PVC plastic door and window profiles will be more widely used and developed in the coming future.

Technical Highlights

● The PVC profile production line produced by Guangdong Blesson Precision Machinery Co., Ltd. is famous for its high efficiency, convenient operation as well as continuous automation. Most importantly, our PVC profile production line has strong applicability in many fields.

Blesson PVC Profile Conical Twin Screw Extruder

● Our PVC profile production line is equipped with a conical twin screw extruder, which can apply to thermoplastics. The professional design of conical twin screw extruder has excellent performance in high ouput and stable extrusion. Parallel twin screw extruder is also optional for customers who want to produce low calcium carbonate filling content, likes window profile with high quality standard in some regions.

● The extruder adopts high-quality permanent magnet synchronous motor, which is efficient and energy-saving.

● The conical twin screw extruder is equipped with a filter for powder, which is conducive to extrusion and forming.

●The screw and barrel of the conical twin screw extruder is nitrided, which has high wear resistance and long service life.

● The screw flight of the conical twin screw extruder can be divided into sections with different heads and pitches, which can improve the mixing and plasticizing.

● The barrel design of the conical twin screw extruder has integral and compact structure, which ensures simple assembly and efficient production. Additionally, the vacuum venting of barrel can drain the moisture and air from barrel during manufacturing, which helps to make perfect PVC profiles with high quality to our worldwide customers.

● The electrical components are imported from international brands, which include ABB, Schneider, Siemens, etc.

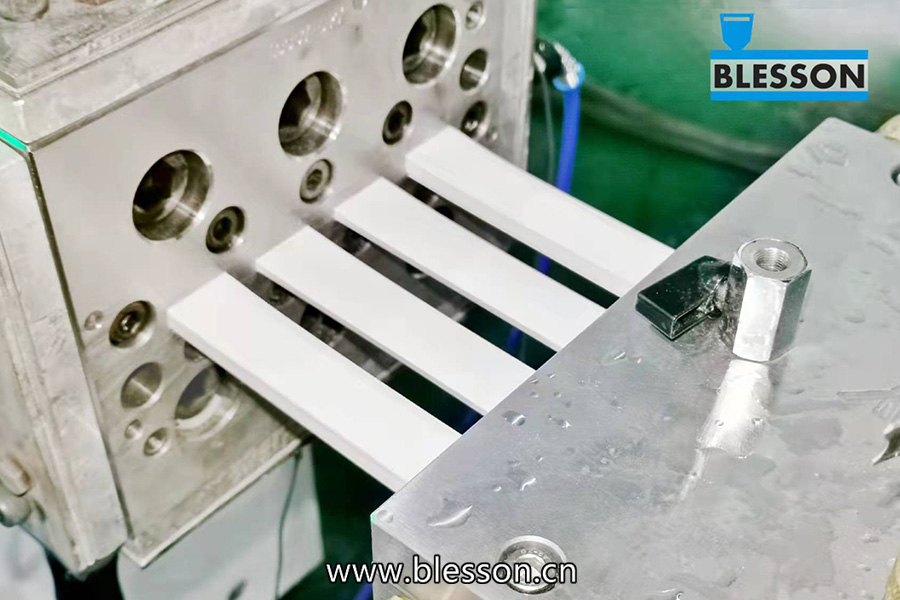

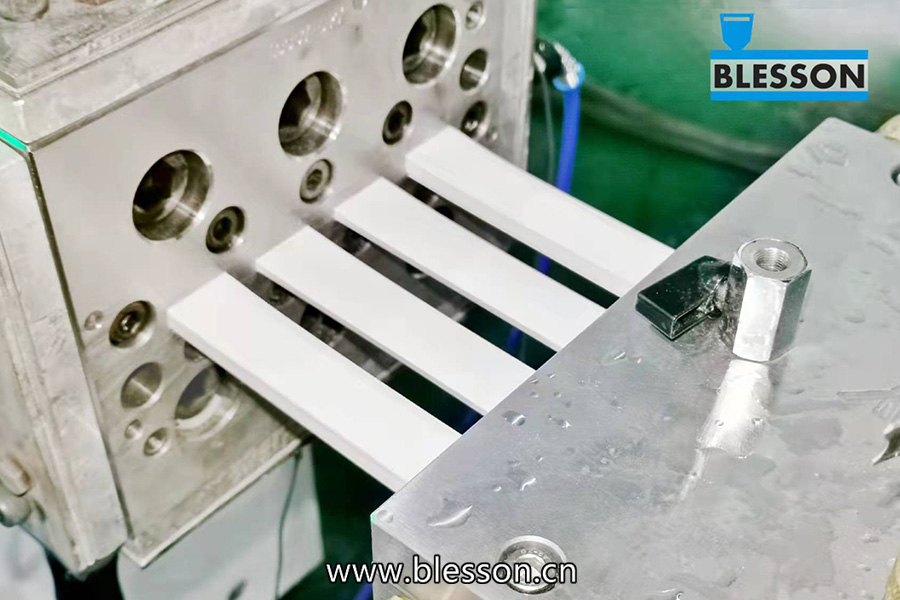

Extrusion Die

● According to the drawings or samples provided by customers, we would carry out a professional analysis and engineering design for PVC profile extrusion die. We will make comprehensive analysis and perfect design according to the size, the direction of flow channel as well as the method of diversion.

● PVC profile extrusion die and calibration are made of 2Cr13 stainless steel.

Having excellent performance of strong hardness and high wear resistance.

● The internal surface of the calibration is polished, thus the brightness of the surface is not affected when the profile is moving through the calibration. It can not only ensure the smooth surface but also guarantee the high quality of PVC profile.

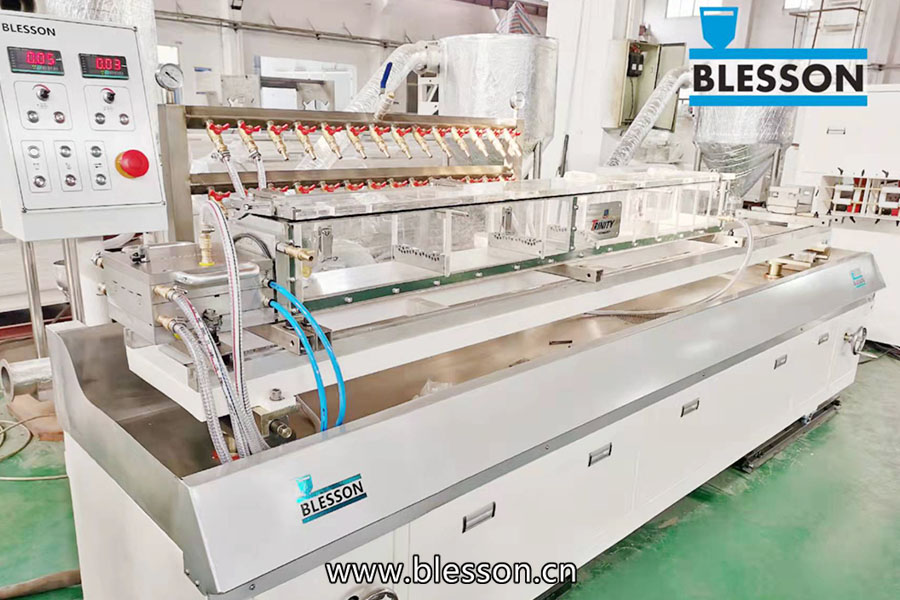

PVC Profile Vacuum Calibration Table

● According to different specifications of PVC profiles, our company configures different vacuum calibration tables for the PVC profile production line.

● The cooling method what we use in the PVC profile vacuum calibration table is eddy current, which has the performance of fast cooling speed and excellent forming.

●With the adjustable horizontal movement, the calibration table of PVC profile can turn forward, rear, left and right.

● The efficient cooling system with the performance of circulating water can accelerate the speed of production for PVC profiles.

● The electric cabinet of the calibration table is waterproof, which make sure that the electrical components won’t get damaged in the electric cabinet.

Haul Off Unit

● According to actual requirments of customers, our company will provide belt or caterpillar haul off unit.

● The hauling speed of the haul off unit is stable and adjustable.

● The rubber block of the caterpillar haul off unit can also be customized according the requirments of clients.

●The installation method what we adopt is screw-type, which is firm and reliable.

Cutting Unit

● According to the specifications of different PVC profiles, our company configures with cutting methods of saw, blade as well as swarf-free cutting.

● For smaller specifications of PVC profiles, our company is equipped with a hauling & cutting combination unit. The cutting unit adopts swarf-free hot cutter, which is flat and smooth. The hauling & cutting combination unit adopts the method of pneumatic synchronization to ensure the performance of precise synchronization.

●PVC profile cutting unit is equipped with strong suction device for collecting the dust, which can effectively reduce the environmental pollution of workshop and protecting the cutting chamber system, as well as prolong the service life of the machine.

● Our company can customize the PVC profile production line according to the cross-sectional drawings or physical samples of the product.

● According to actual demand of our customers, our company can provide single-station or double-station PVC profile production lines to improve the efficiency of production.

Product Model List

|

PVC Profile Production Line |

|||||

|

Line Model |

Panel Size (mm) |

Extruder Model |

Max Output(kg/h) |

Length Of Line(m) |

Installation Power(kw) |

|

BLX-150PVC |

150×50 |

BLE45-97 |

120kg/h |

21 |

100 |

|

BLX-150PVC (Water bucket) |

150×50 |

BLE65-132 |

280kg/h |

21 |

115 |

|

BLX-150PVC (Window profile layering) |

150×50 |

BLE55-110 |

200kg/h |

22 |

100 |

|

BLX-150PVC (Trunking) |

150×50 |

BLE55-110 |

200kg/h |

22 |

92 |

|

BLX-250PVC |

250×60 |

BLE65-132 |

280kg/h |

25 |

125 |

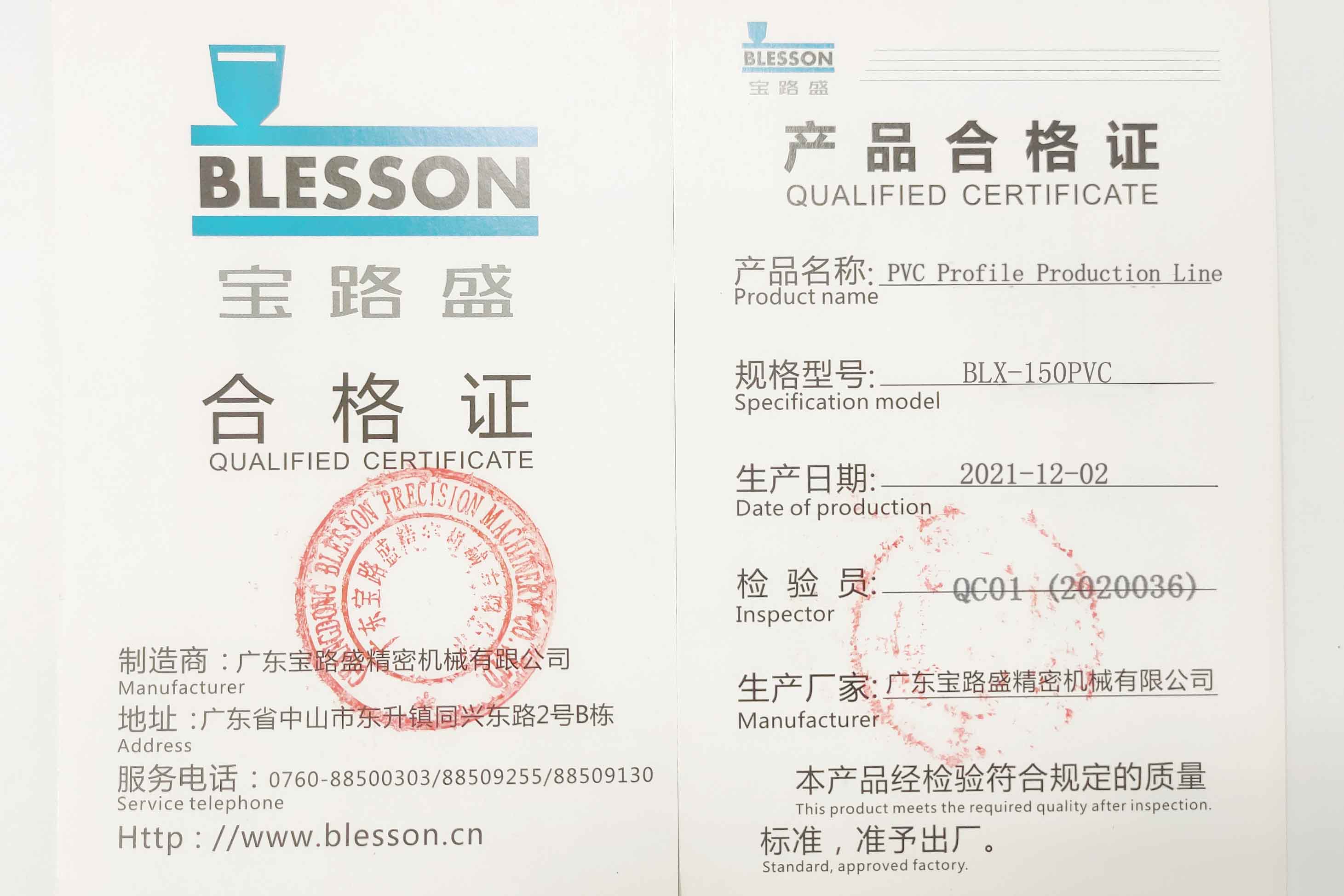

Warranty, Certificate Of Conformity

Guangdong Blesson Precision Machinery Co., Ltd. provides a one-year warranty service. During the use of the product, if you have any questions about the product, you can directly contact us for professional after-sales services.

Guangdong Blesson Precision Machinery Co., Ltd. provides product qualification certificates for each product sold, ensuring that each product has been inspected by professional technicians and debuggers.

Company Profile